Process technology Food, feed & fine chemicals by Glatt Ingenieurtechnik, from particle building using fluid bed technology to the entire plant in turnkey “ready to produce”.

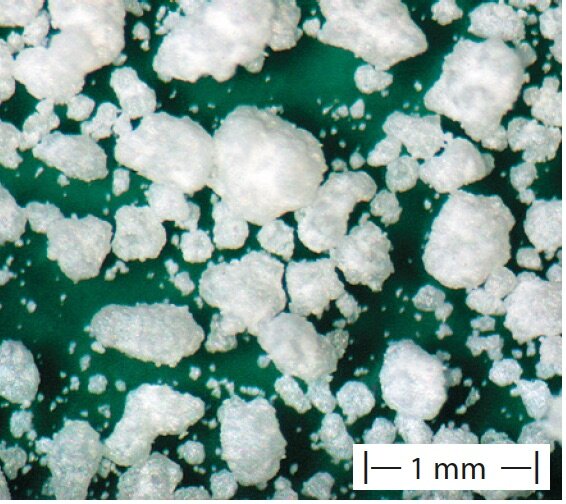

Glatt Process Food Technology, Feed & Fine Chemicals offers advanced fluid bed technologies for a wide range of applications in the fields of food processing, human and animal nutrition, cosmetics, chemistry and fine chemicals. The competence of Glatt Ingenieurtechnik lies in the development of innovative solutions for the optimization and recovery of powders, agglomerates or pellets. The substitution of powders and liquids by dust-free particles and granules is the subject of many applications in many industries. Thanks to the different coating techniques mastered by Glatt, the qualities of the granules can be brought to a tailor-made functionalization.

Both continuous and batch production can be achieved using Glatt equipment. As a pioneer company in fluidized bed technologies Glatt provides solutions that range from the design of a particule to the engineering and turnkey completion of the whole plant.

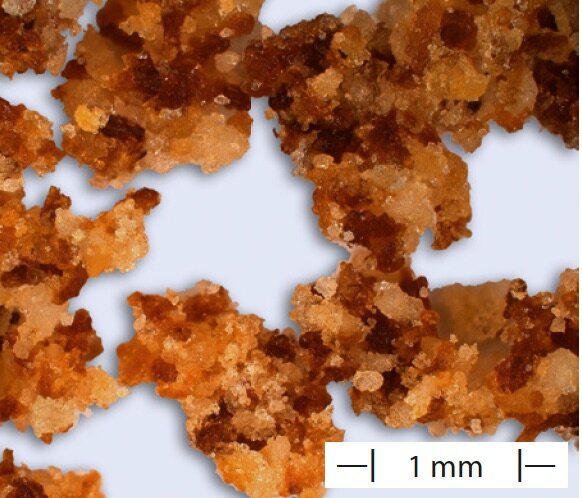

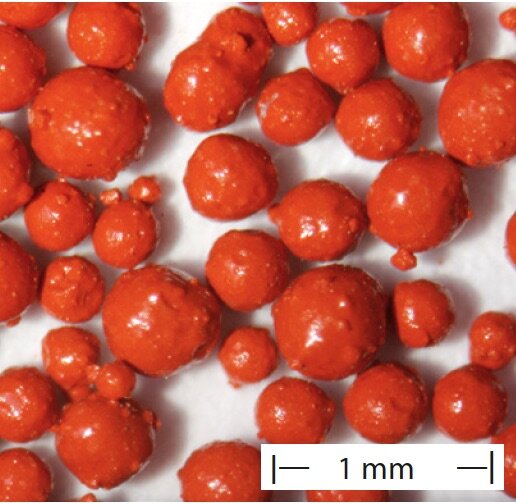

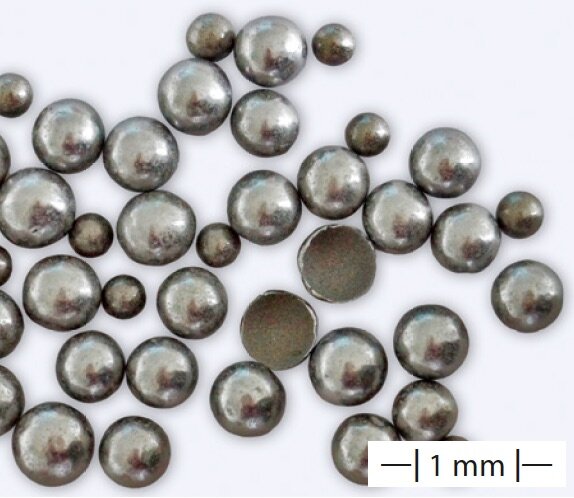

Spray granulation is the drying of liquid while simmultaneous building particle size. Seeds for the granulation can be charged (external seeds). Alternatively the seeds are formed within the processing chamber by abrasion. Compared to agglomerates, these granules are harder and more dense…

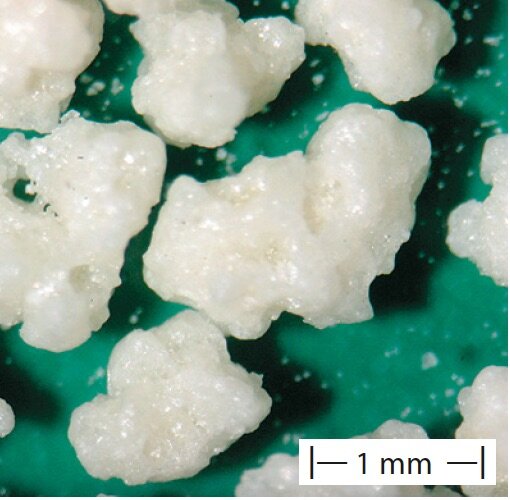

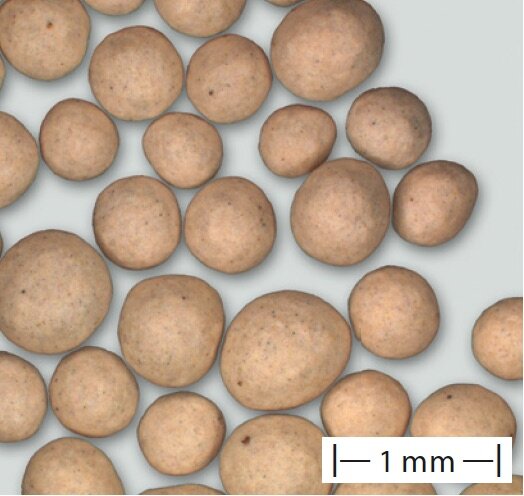

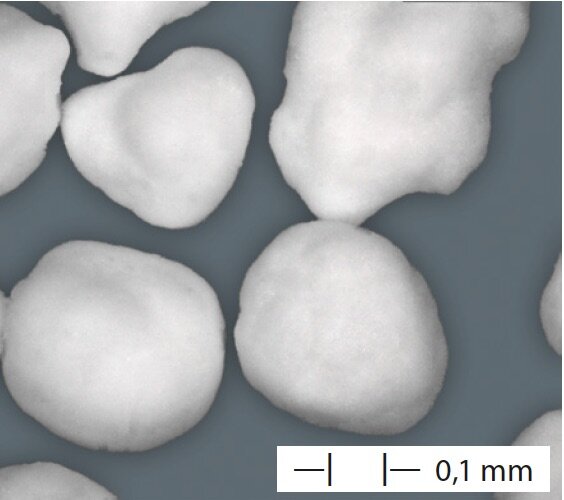

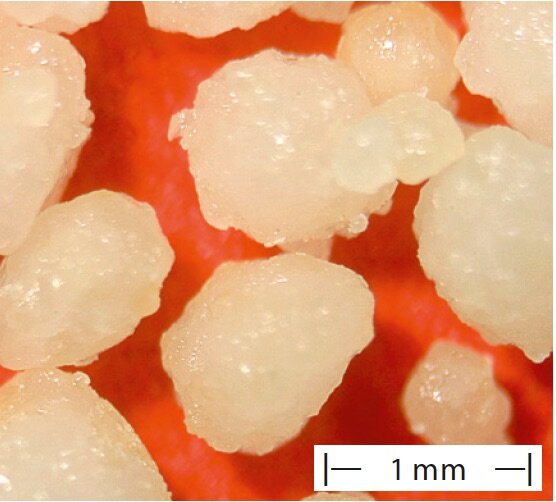

Agglomeration in the fluid bed has been used for a long time to form granules from a powder. The fluidized powder is wetted until liquid bidges are formed between the particles. Water, solutions, suspensions or melts can be spryed to meet the desired product quality. This technology allows less dust, a better flowability ...

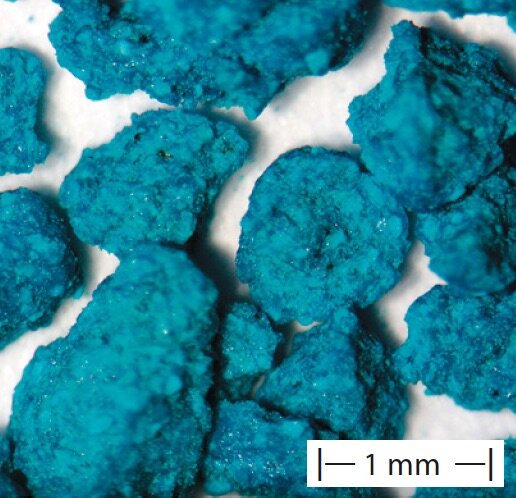

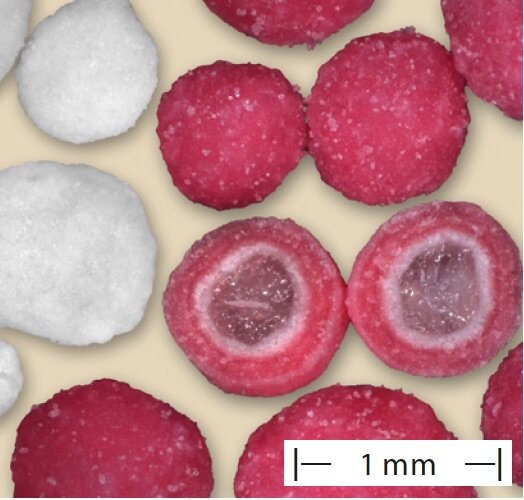

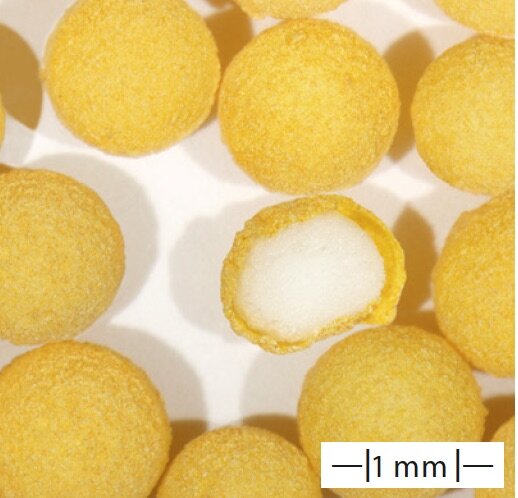

Coating and encapsulation with liquids consists in achieving a change of their surface properties and by this mean working out a different behavior of the particles. Glatt offers several processes for the coating according the type of particles. Coating liquids can be solutions, suspensions, melt…

The technology center

At the Weimar Technology Center, Glatt Ingenieurtechnik GmbH provides its customers with all the process equipment needed for the tests. The dedicated measuring instruments allow to follow in real time the evolution of the product in terms of particle size distribution, relative humidity, apparent density, attrition, adsorption-desorption, in order to offer conducting 360 ° investigations.

Reach your product ideas with Glatt technologies.

Since 1960, Glatt has been involved in the research and development of powder design technology. The fluid bed and spouted bed equipment developed by the German pioneer has since conquered the world. Glatt has not hesitated to introduce new process advances and offers its customers the benefit of unique know-how in spray granulation, spray agglomeration, powder coating, liquid and powder coating, micro-encapsulation, and generation of pellets.

Agglomeration

Granulation

Coating

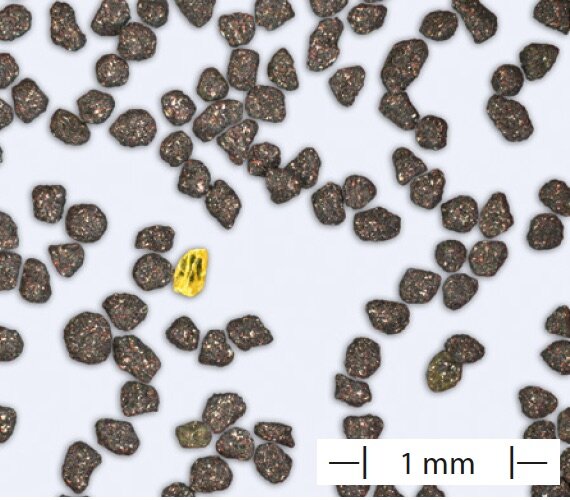

Powdering

Encapsulation

Spray granulation, Agglomeration, Coating, Encapsulation, Particle building… On ProCell Labsystem.

The treatment of fragile raw materials must be mastered using gentle fluidized bed processes. Especially for the natural or volatile product, using granulation, agglomeration, spray coating or microencapsulation ProCell Labsystem from Glatt allows adequate particle building and functionalization. Particularly appropriated for performing high efficiency particle systems having specific properties under low temperatures, the ProCell is Glatt Ingenieurtechnik’s pilot unit flag ship.

Process and plant engineering for the pharma, feed, food and fine chemical sectors.

Glatt is a pioneer in fluidized bed equipment. The solutions range from particle design equipement and konwhow, to complete engineering and turnkey execution of an entire plant, in the pharmaceutical, animal nutrition, global life science and biotechnology fields.

From the basic engineering to the turnkey delivery of a "Ready to Produce" plant thanks to Glatt Ingenieurtechnik’s multisectorial competences.

Industrial site construction has been the core business of Glatt Ingenieurtechnik for more than 50 years. Glatt’s customers can achieve their production goals by getting turnkey, high performance and easy to operate solutions. The standard service scope includes all process-relevant peripherals (pumps, fans, HVAC, control systems). Glatt offers know-how on upstream and downstream installation of process equipment that be extended to complete "ready to produce" deliveries, including civil works and buildings. Equipment, regardless of brand, is installed and connected by Glatt specialists. The client is assured of achieving his objectives by having one single interlocutor.