VISO | the smart containment technology

The containment isolators designed by SCHEDIO allow the operator to carry out manipulations while maintaining visual control through a safe and ergonomic hermetic barrier, in order to create a controlled environment for testing purposes.

There cannot be any compromise when it comes to operator safety

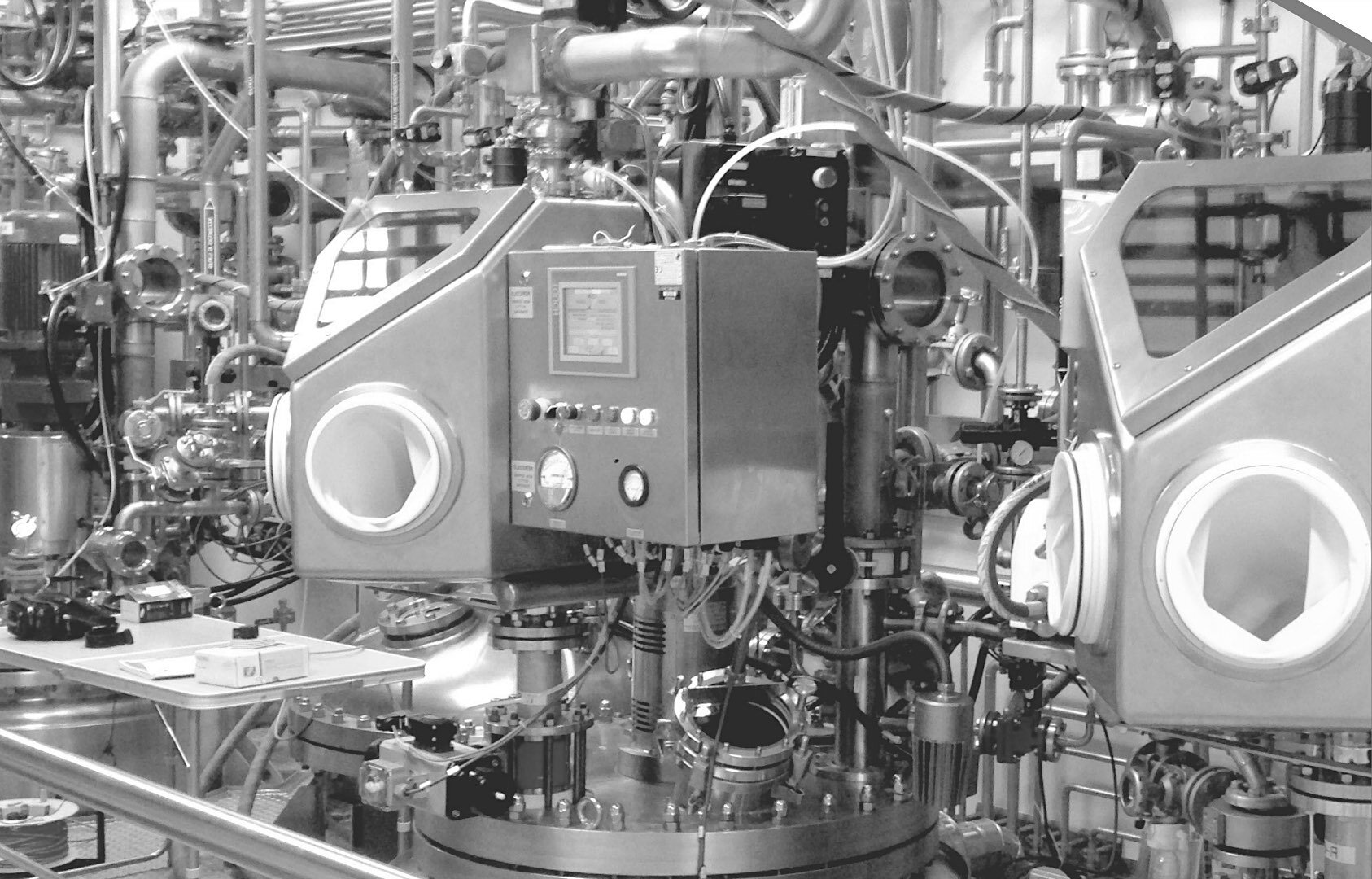

Isolators for handling HPAPIs, the VISO concept is a modular and versatile glove box to be used for sampling, dispensing and loading highly active powders, such as on reactors. Thanks to its interchangeable base, the VISO range can be used for all other applications. VISO is available in ATEX version and is designed to allow inerting and bio-decontamination processes.

As part of a containment linked to micronization steps of highly active powders, but as well in many other applications, SCHEDIO has developed its range of VISO isolators allowing to reach OEL containment level < 10ng / m3 (SMEPAC test).