Taylored isolators for high containment solutions.

Highly potent active pharmaceutical ingredients (HPAPIs) require specialized handling. SCHEDIO provides taylored glove box able to cover specific needs in wide application domains.

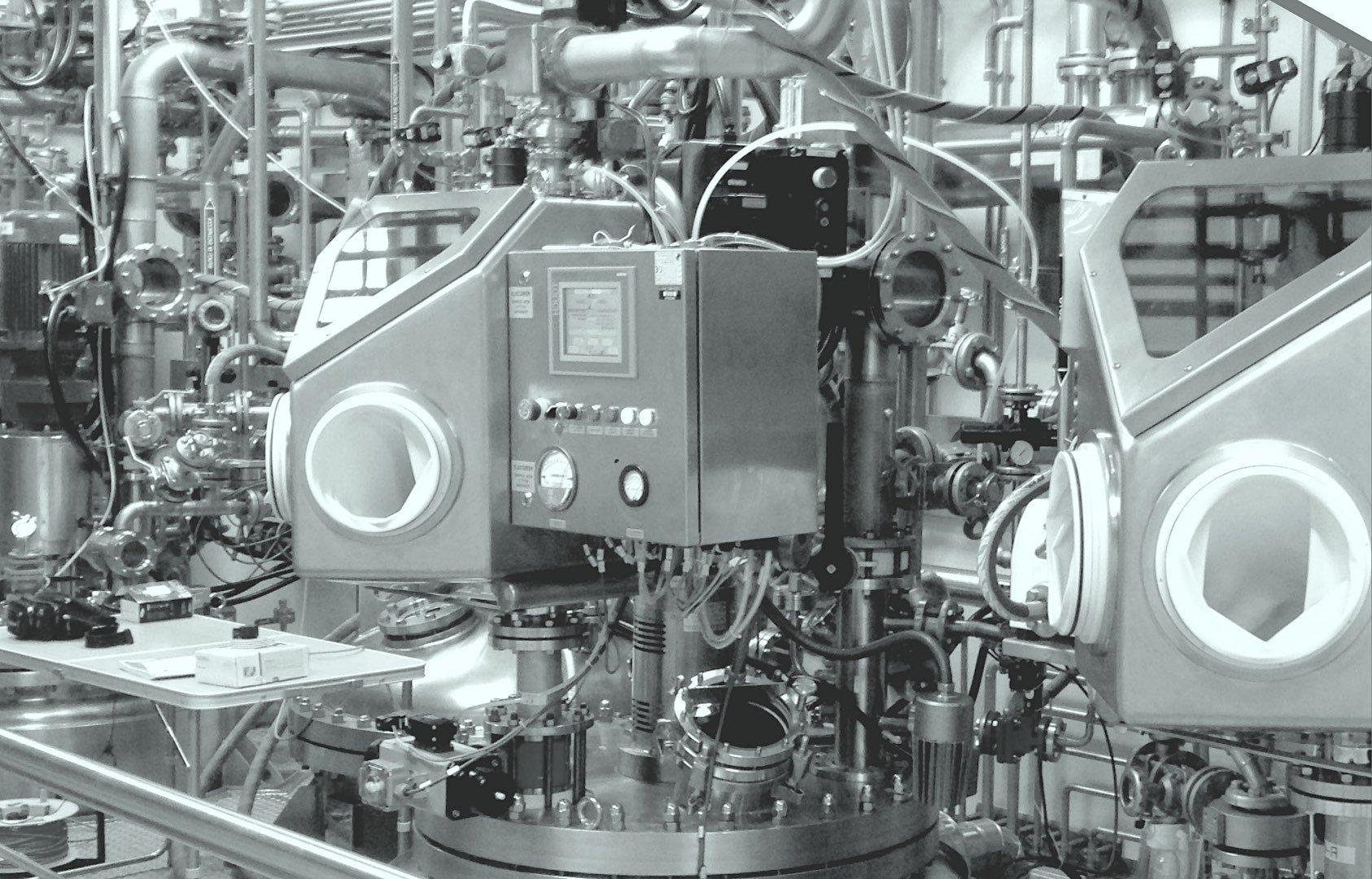

SCHEDIO developed process solutions to meet the growing request of the pharma market whose trend is to increase the containment level and safety particularly for the micronization of high potent ingredients (HPAPIs).

OEL< 10 ng/m3 (<0.01µg/m³) SMEPAC tested

Standardized equipment series for micronization application

This single chamber isolator allows the integration of a SCHEDIO SSM150 spiral jet mill to perform fine grinding operations of HPAPI powders. This solution is particularly suitable for highly pharmacological active ingredients (for example, active ingredients developed for oncology)

GloveSpeedtester - Atex

The smallest holes detected in very short time

SCHEDIO’s R&D department has developed and realized a new efficient glove leak tester able to detect the presence of the smallest holes in a very limited time thanks to a new dedicated algorithms calculation and a reduced stabilization time.

The glove leak tester is available in its ATEX configuration upon request.

Viso Versatile Isolator for HPAPI Handling

Sampling, Dispensing and HPAPI powder loading in reactors

VISO Concept is a modular and versatile isolator to be used for Sampling, Dispensing and HPAPI powder loading in reactors. Thanks to its interchangeable base VISO can be used for all the reported applications. VISO is available in the ATEX version and it is proper designed to be submitted to the inertization and bio-decontamination process.

SCHEDIO design and manufacture containment systems capable of guaranteeing high standards of safety and protection for the operator, the product, and the environment. Daily exposure to active ingredients can be extremely harmful to operators and the environment, especially in the long term. Exposure of the process to pollution and contaminants may also impact the quality of the final product. Following the latest SafeBridge and cGMP guidelines, we can guarantee the highest standards of safety and protection for the operator, the product, and the environment by designing and manufacturing state of the art protective rigid isolators with containment levels (SMEPAC certified) as low as <1ng/m3 (8hTWA). SCHEDIO can design both modular and fully tailored containment solutions, depending on the process flow and the characteristics of the product to be contained.